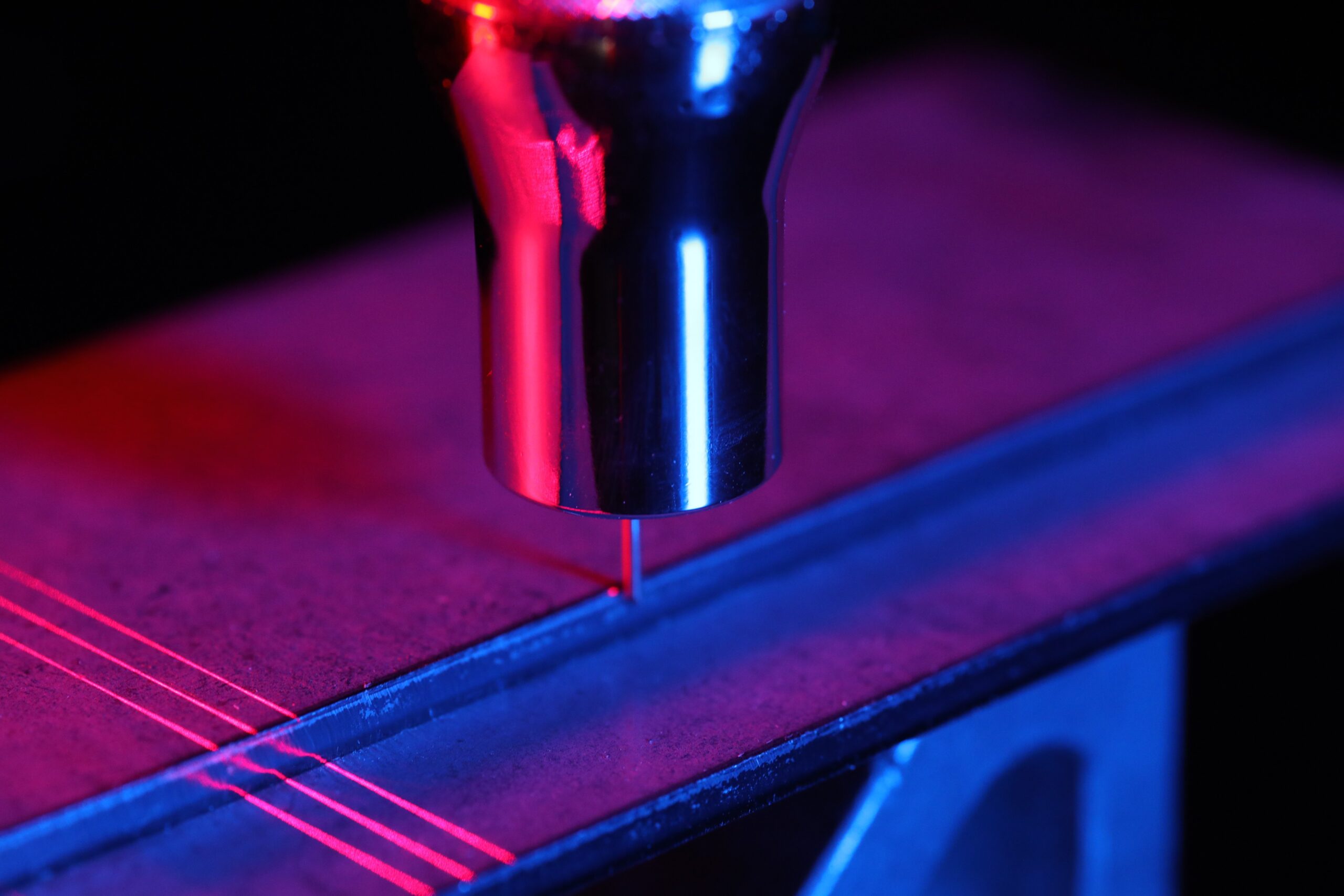

The optical sensors for seam tracking support automated welding processes with both arc and laser. The active seam detection scans the edge offset at the joint without contact using light beams and thus ensures the precise positioning of the tool at any time.

All our sensors are designed for applications even in harsh industrial environments – e.g. in welding cells – and score with their pronounced robustness. The integrated stray light filtering ensures smooth operation even in the near-process area and on adverse surfaces such as stainless steel and aluminum alloys.

A wide variety of joints, including the difficult-to-detect I-seam at the butt joint, are detected.