Laser Beam Analysis

Overview

The laser has established itself as a valuable tool in many markets. The characterization and inspection of this tool impose high demands on the measurement technology. Different measurement methods can be used to cover the variety of necessary functions.

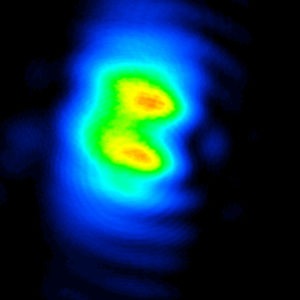

Beam Profiling

Beam profiling is a tool for speeding up processes by providing an optimized laser spot. Control of beam shape and position using a beam profiler ensures the continued high quality of the process.

This fundamental function of laser beam analysis is provided by the Beamlux software. The contained software tools such as 2D-zoom and spot tracking or the time-dependent plotting of many calculated results are ideal tools for quality control. They are employed wherever a precise positioning or monitoring of laser beams is relevant.

Metrolux measurement systems are set up for the many requirements in Laser systems and related applications. They are employed worldwide in many systems even for UV and IR wavelengths that are normally inaccessible by CCD or CMOS sensor technology.

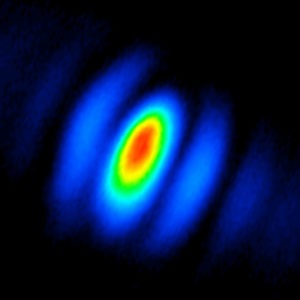

Focus Measurement

Focus measurement helps to increase process speeds by helping to optimize the laser spot. Distortion-free attenuation and magnified imaging enable control over the intensity distribution and position of a laser focus. This is an important tool in process monitoring.

Metrolux provides Measurement systems that are optimized for very different requirements for a focused laser beam such as wavelength, power density, numerical aperture and spot size. The tools contained in the Beamlux software such as 2D-zoom and spot tracking or the time-dependent plotting of many calculated results are ideal for the analysis and optimization of the intensity distribution in the laser focus.

The laser focus has been recognized as a valuable tool in many areas of materials processing. The automotive industry uses focused laser beams for remote welding of vehicle body parts, the display industry for cutting glasses and the separation of layers while the solar industry uses them for cutting and scribing silicon wafers.

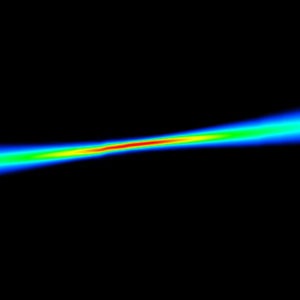

Line Focus Measurment

Line focus measurement serves to enhance the process speed by providing an optimized laser line focus. To ensure a lasting high quality of productoin processes one must continuously monitor the line width, intensity distribution and homogeneity. This requires a quick measurement at high resolutions.

Line shaped laser foci with lengths of up to 3000 mm enable large area processin of many materials. Especially in large scale mass production settings this requires the constant monitoring of the employed laser tool. One instance of the efficient use of laser line foci is the OLED and LED display production. Lasers of vaying wavelength, line lengths and widths and intensity homogeneities are employed here. Metrolux provides measurement systems with the specialized Beamscan or Linescan software bundles that are optimized for the line focus anaysis to monitor the continously high quality. Some Metrolux UV systems are available for extended line focus or area scan measurements even at UV wavelengths such as 193 nm.

This method is predominantly employed in the display and semiconductor industries.

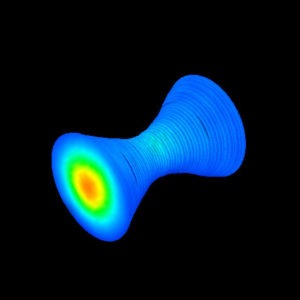

Caustic Measurement (M²)

The measurement of a laser’s caustic allows a precise characterization of the beam’s quality. The M2-Tool within the Beamlux software is optimized for measurements of the intensity distribution along the laser beam caustic conforming to the ISO 11146 standard and provides this at a high speed and with the highest level of reproducibility.

The characterizatoin of laser sources is of paramount importance in the production process of high quality laser systems. The choice of beam sources for integratd systems can be made and the systems can be planned based on the parameters defined in the standard. Metrolux Measurement systems are dsigned for a quick high-precision measurement of the laser’s beam parameters according to ISO11146. They can be easily integrated into production processes due to the included remote control features.

This type of measurement is predominantly used by laser manufacturers and systems integrators to precisely specify lasers and laser beams. To this end the Metrolux software provides conclusive measurement reports.