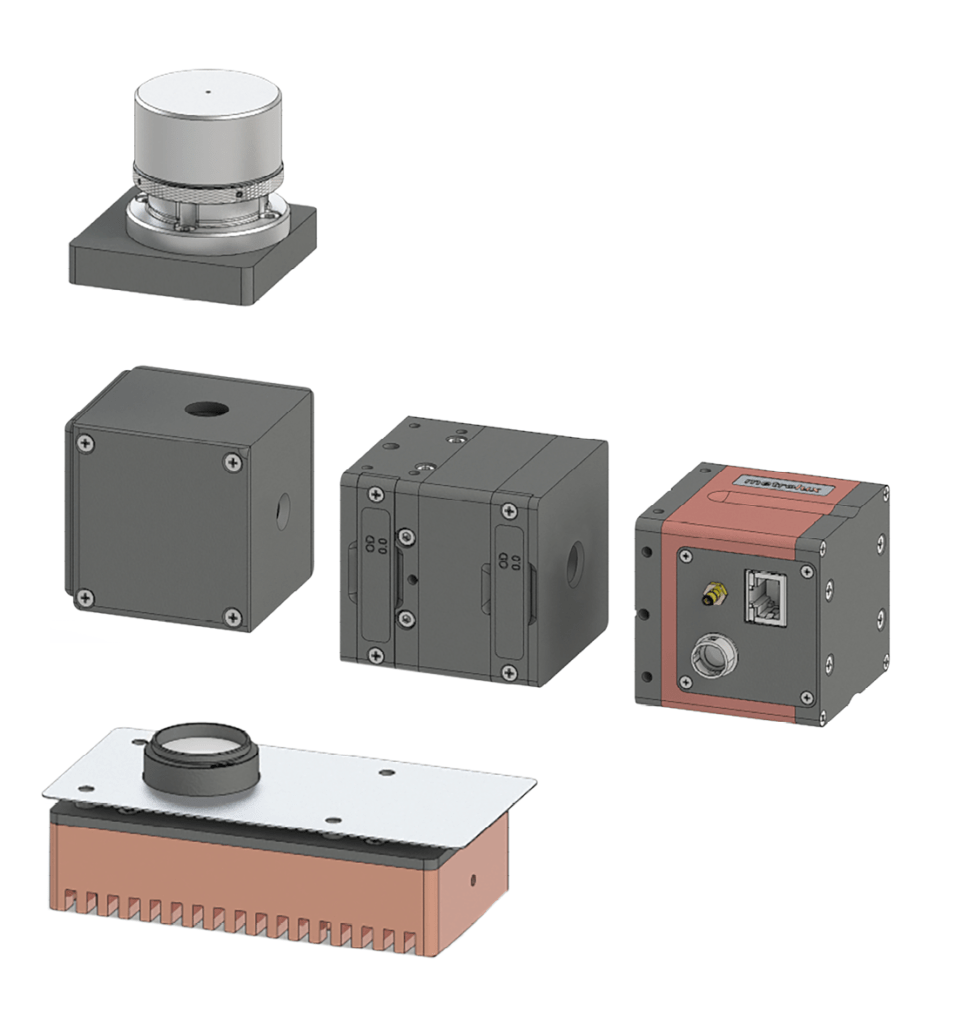

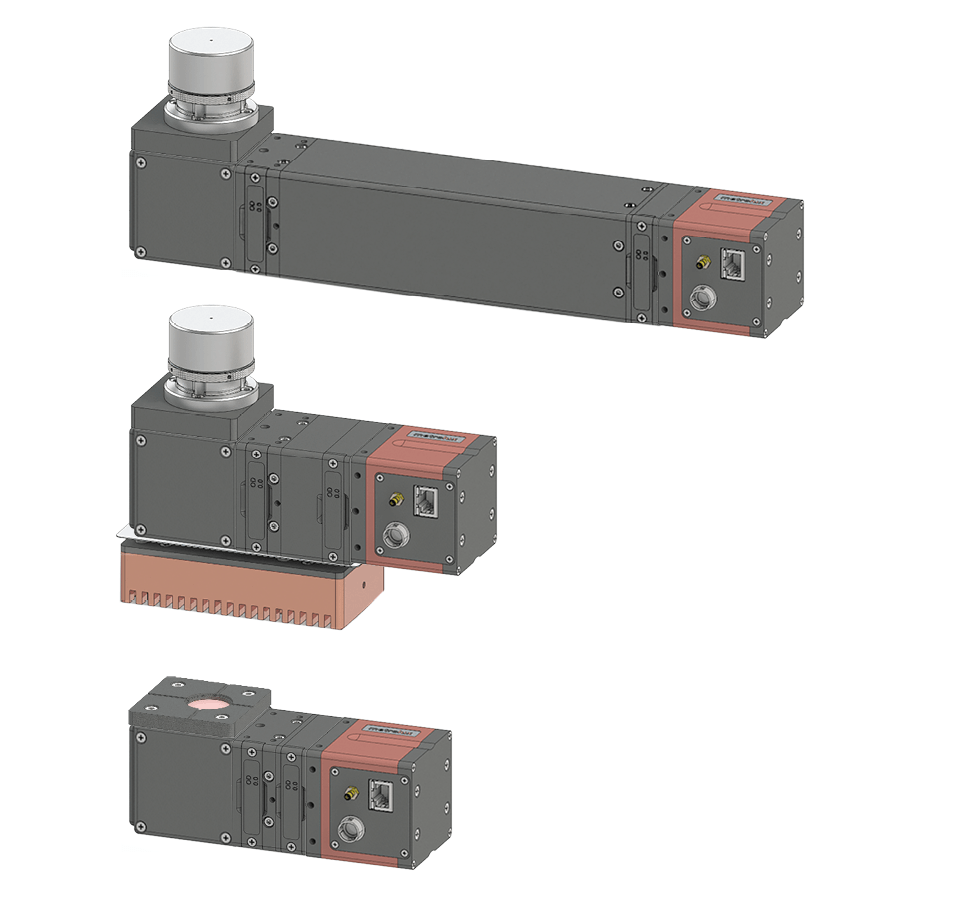

The camera-based beam profiler system by Metrolux is a modular system that can be perfectly tailored for every application. Possible system configurations can be adapted for a multitude of applications: Raw beam analysis as well as focused beam and line focus analysis are possible in a wavelength range between 343 nm and 1100 nm. Depending on the application, lenses with magnifications between 5 x and 50 x are used.

Thanks to the rugged and compact design (smallest possible dimensions: 112 x 163 x 60 mm) and easy integration (GigE-Vision interface with PoE, XML interface in the Beamlux software), Metrolux beam profilers are employed worldwide in industrial environments. Their flexibility and multiple accessories have made them popular for use in laboratories.

Depending on the configuration, the beam profiler can be used for an ISO-compliant characterization of laser beams for various laser applications in many different industries. From display industry (e.g., laser annealing, laser lift-off, laser cutting, etc.) to adaptive manufacturing (3D print SLM, for example), to material processing (such as laser cutting, welding, drilling or marking) and much more.

The range of applications comprises raw beam and focused beam measuring, as well as line focus measuring, and caustic strength determination.

The devices are capable of measuring different laser wavelengths, cw- and pulsed lasers with an output of up to 500 W*, and beam profile dimensions from 10 μm* up to 2000 μm*.

*depending on the specific configuration

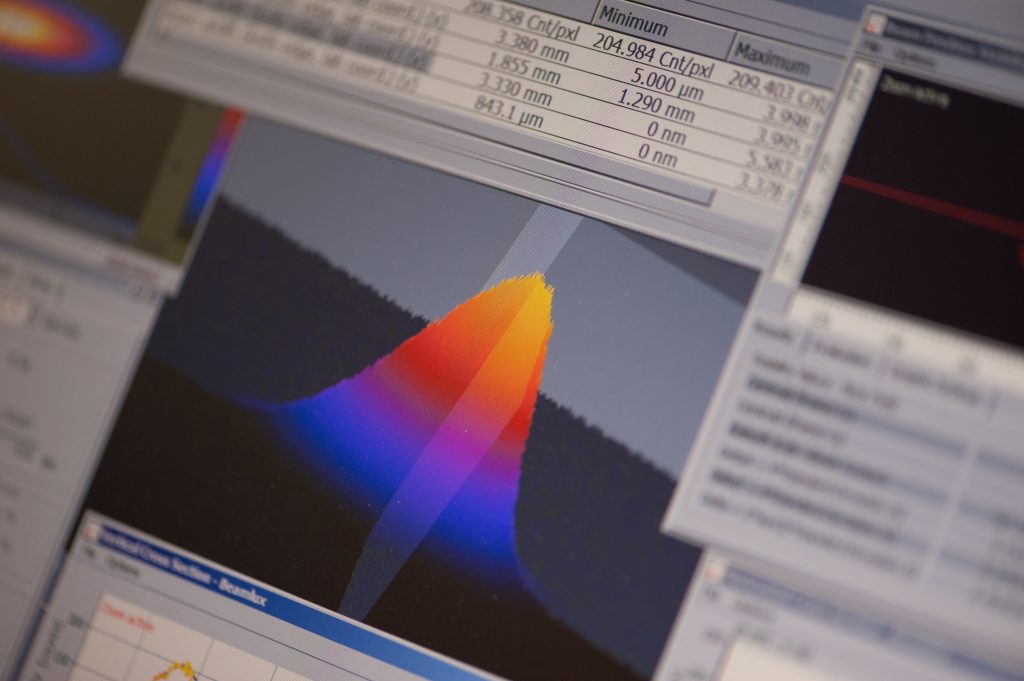

Beam profile:

Laser line:

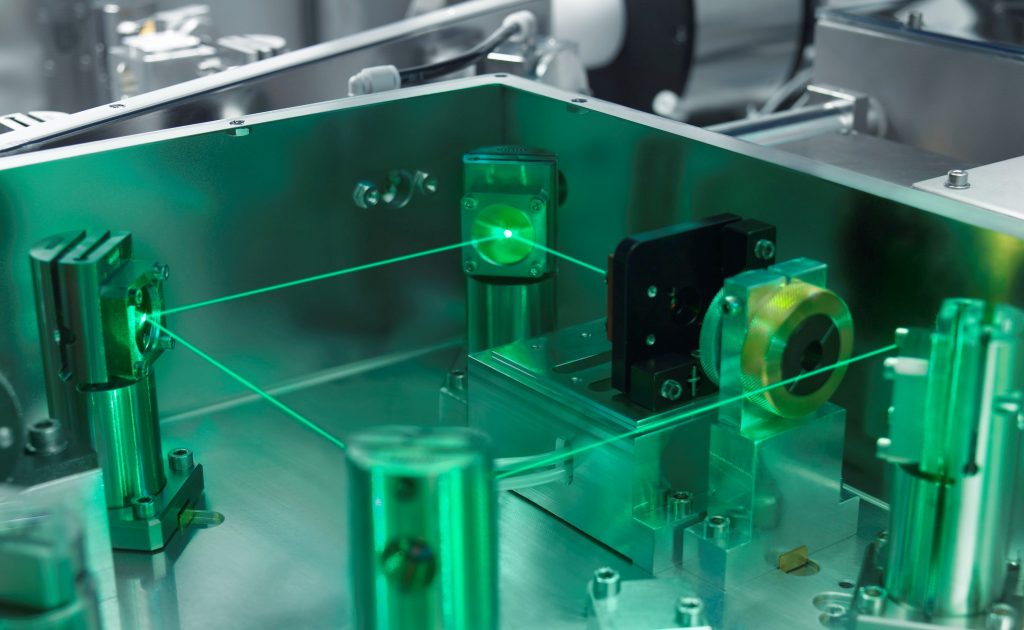

Via the opening in the tube aperture of the lens module, the laser beam to be measured is coupled into the device, providing for orientation in x- and y-direction. In a configuration without lens module, the cross hair on the lid of the device aperture is used as orientation for alignment. The lens module reproduces a magnified beam which is then guided through the attenuator module where the beam is divided.

The emission window at the bottom of the attenuator module releases a large portion of the laser beam from the device where it then can be captured by the optional absorber module. This concept allows for measuring times of different lengths, depending on the laser power used and an air- or water-cooled absorber. The attenuator module directs a small portion of the laser beam to the filter module. Filter inserts can be used here to further attenuate the beam before it strikes the camera.

In the Live mode of the software, the laser beam (or laser line) can be centered using the position of the beam profile on the sensor. The focus position is subsequently determined by moving in z-direction. The smallest beam diameter or the thinnest line width identify this position. The power can now be increased according to the application and the selected device configuration, and beam analysis can be initiated.

Are you interested in our beam caustic measuring devices for M² analysis? We would be happy to advise you personally.

© metrolux 2023