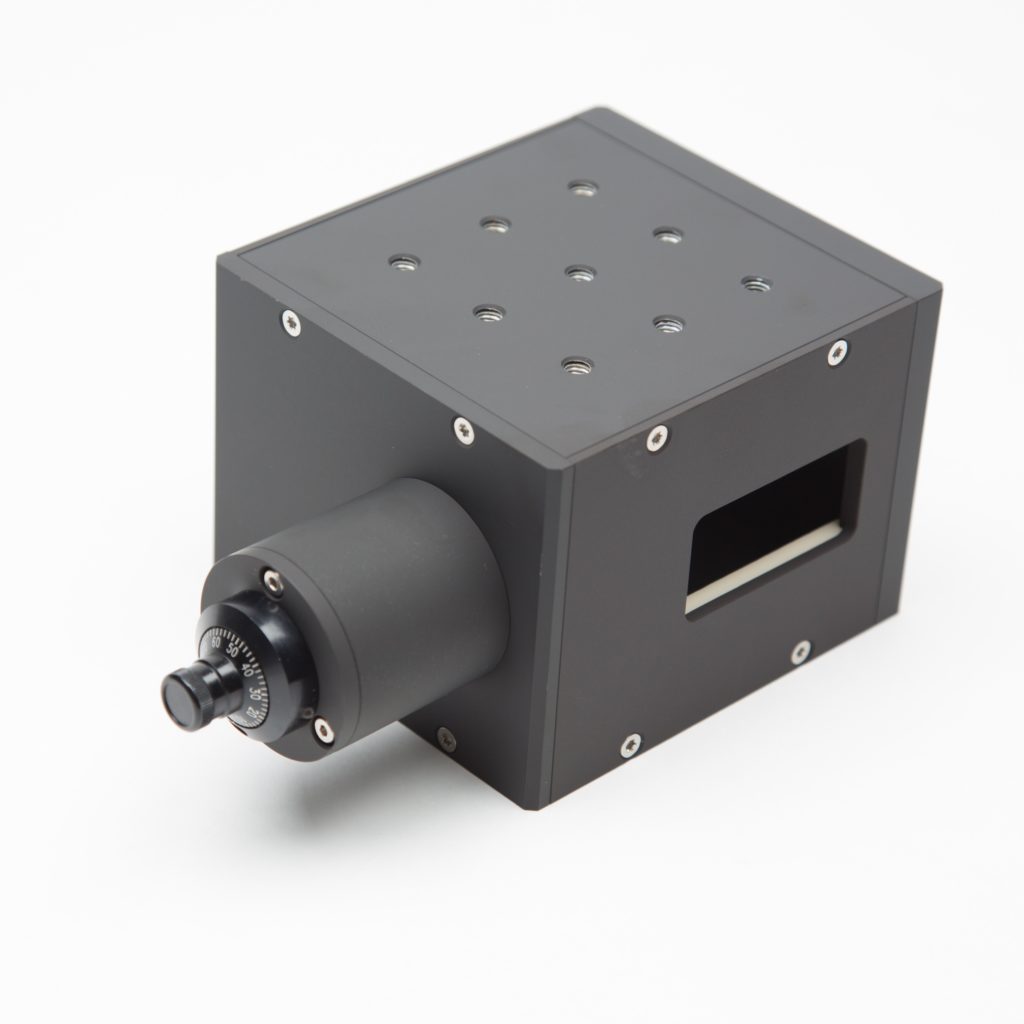

The variable beam attenuator allows for precision adjustment and stabilization of laser power for highest reproducibility of laser processes.

Variable beam attenuators (VA) maintain a constant output power for laser beams with high pulse energies throughout the production process. Typical wavelengths of applications are those of excimer and YAG lasers. The VA are, however, also suitable for the cw mode and are available for many other laser wavelengths.

Variable beam attenuators consist of a dielectric attenuation plate and a compensator plate. The variation of the transmitted energy level is achieved by tilting the plates. The angle is adjusted using an adjusting knob or a stepper motor. Tilting the compensator plate at the opposite angle of the attenuation plate prevents the induction of a beam displacement. The attenuated beam passes through the optical plates. The remaining beam energy is reflected and absorbed within the attenuator housing.

Since the incidence angle of the laser beam to the attenuator plate determines the level of attenuation, the transmitted energy can be adjusted continuously in the range of about 95 to < 4 percent – depending on the wavelength and coating. This corresponds to an attenuation by a factor of 1.05 to > 25. By means of another optional attenuation plate instead of the compensator plate an even stronger attenuation can be achieved.

Each specific VA may only be used for a narrow wavelength range. Are you missing the VA suitable for your wavelength? Please contact us!

Benefits:

Are you interested in our beam caustic measuring devices for M² analysis? We would be happy to advise you personally.

© metrolux 2023